Collision Repair

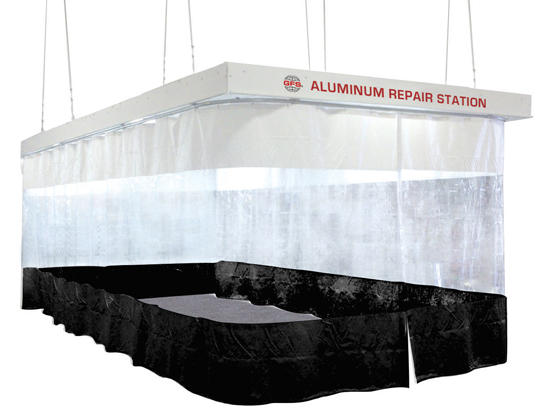

Aluminum repair is a unique process that requires a dedicated set of tools and an isolated area in order to prevent contamination from compromising the repair.

In addition to aluminum repair, GFS' Aluminum Repair Station Plus can be used for spot painting and other repairs, for maximum productivity and flexibility.

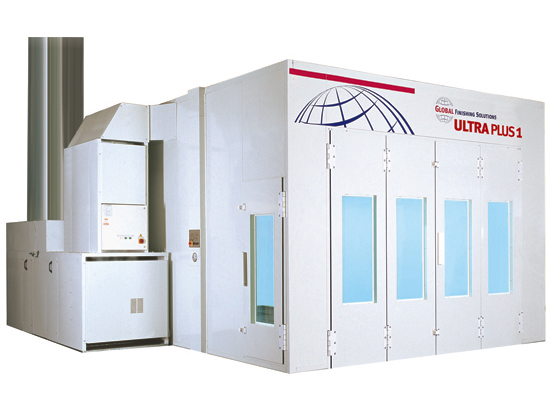

Code Compliance -- GFS guarantees that our products meet or exceed all of the applicable codes related to the equipment. Our engineers regularly follow and contribute to the advancement of codes and standards that affect the industries that we work in. One of our engineers currently serves on the NFPA Technical Committee on Finishing Processes, a key standard in the finishing industry.

Aluminum Repair Station Plus exhaust system is intended for priming and prep processes only, and is not suitable for extraction or containment of explosive aluminum dust. An aluminum dust extraction system must be installed and used for aluminum repair work.

Features

- Semi-downdraft airflow with overhead filtered plenum (single).

- White pre-coated galvanized steel construction.

- Heavy-duty, non-combustible curtain walls.

- Column supported or suspended from shop ceiling.

- Drive-through configuration with back curtain wall.

- Four-tube light fixtures Exhaust.

- Exhaust filter isolation shield.

- 9" double-width, double-inlet, forward-intake fan.

- Basic control panel for lights and fan.

- Options -- Back wall tool cabinet, light reflectors, Exhaust ductwork and weld view curtain.

- Dimensions -- 27', 30' or 33' long, 14' or 16' wide, 9' or 12' high (all dimensions internal), with 6, 7 or 8 light fixtures.